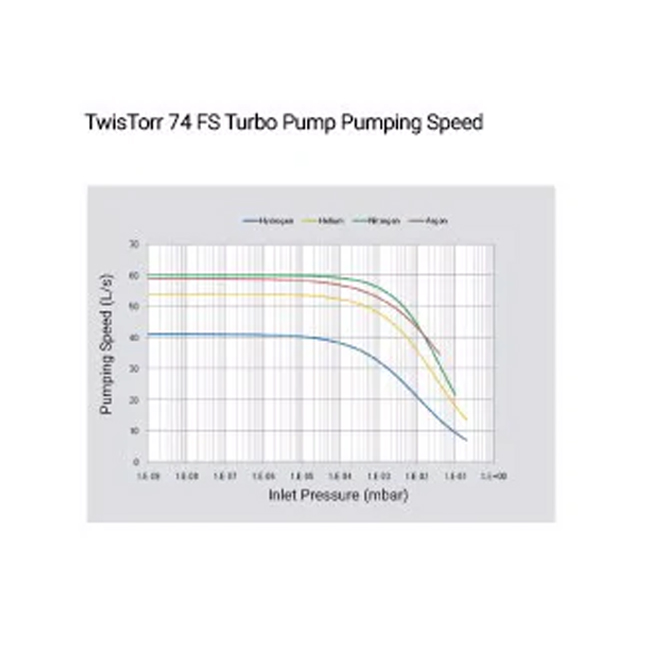

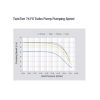

| Pumping speed |

KF40 |

CFF 2.75″ |

ISO 63 |

CFF 4.5″ |

| N2 |

44 L/s |

50 L/s |

60 L/s |

60 L/s |

| He |

33 L/s |

40 L/s |

54 L/s |

54 L/s |

| H2 |

28 L/s |

31 L/s |

42 L/s |

42 L/s |

| Ar |

40 L/s |

51 L/s |

59 L/s |

59 L/s |

| Max Gas Throughput (*) |

Air Cooling |

Water Cooling |

| (35°C ambient temperature) |

(25°C water temp. / 35°C ambient temp.) |

| N2 |

130 sccm |

130 sccm |

| Ar |

80 sccm |

80 sccm |

| (*) Backing pump 5 m3/h |

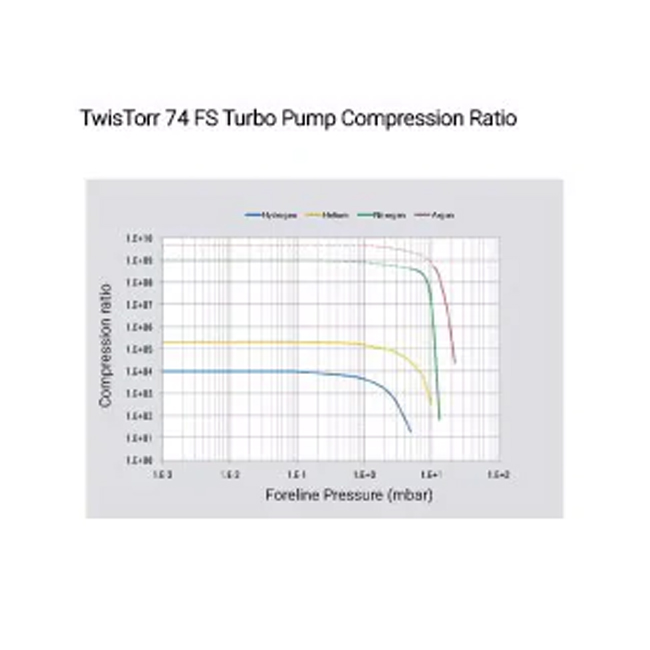

| Compression ratio and foreline tolerance (**) |

| N2 |

1.0 x 109 |

>12 mbar |

| He |

2.0 x 105 |

>10 mbar |

| H2 |

1.0 x 104 |

>04 mbar |

| Ar |

> 1.0 x 109 |

>14 mbar |

| (**) Foreline Tolerance defined as the pressure at which the turbopump still produces a compression of 100, estimated in water cooling mode |

| Base pressure with recommended forepump |

<5 x 10-10 mbar |

| <3.75 x 10-10 Torr) |

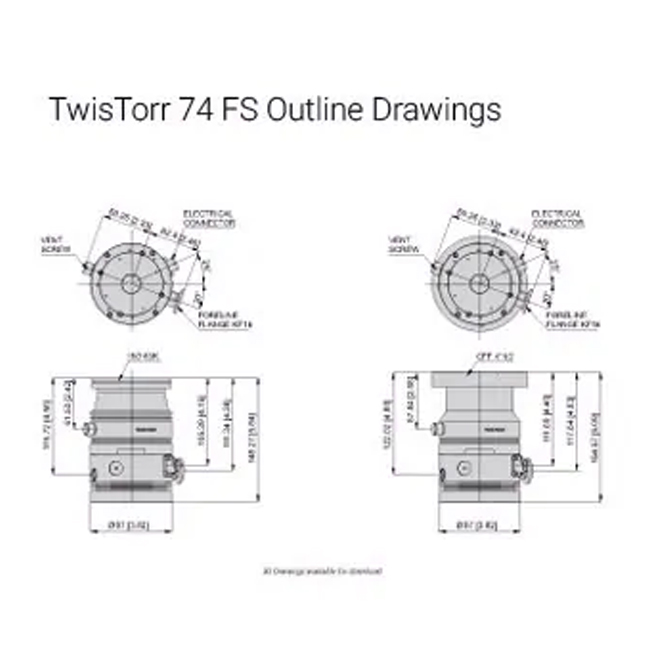

| Inlet flange |

KF 40, ISO 63, CFF 4.5”, CFF 2.75” |

| Foreline flange |

KF 16 NW |

| Rotational speed |

70000 rpm (1167 Hz driving frequency) |

| Start-up time |

<2 minutes |

| Recommended forepump |

Agilent DS 40M / DS 102 Rotary Vane Pump |

| Agilent IDP-3/IDP-7 Dry Scroll Pump |

| Operating position |

Any |

| Operating ambient temperature |

+5 °C to +35 °C |

| Relative humidity of air |

0 – 90 % (not condensing) |

| Bakeout temperature |

80 °C for ISO (120 °C for CFF) |

| at inlet flange |

| Lubricant |

Permanent lubrication |

| Cooling requirements |

| Air cooling |

Forced air (5-35 °C ambient temp.) |

| Air flow temperature +5° C to +35 °C |

| Water Cooling |

Water temperature from +15°C to +25°C Water flow min. 65 L/h |

| Noise pressure level (at 1 mt at full speed) |

40 dB(A) |

| Storage temperature |

-40 °C to +70 °C |

| Max altitude |

3000 m |

| Weight kg (lbs) |

ISO 63 |

2.05 (4.50) |

| CFF 4.5” |

3.50 (7.70) |

| CFF 2.75” |

3.34 (7.35) |

| KF 40 |

2.37 (5.22) |

| Conformity to norms |

| CE, C-CSA-US, RoHS compliant as per 2011/65/UE |

Tiếng Việt

Tiếng Việt