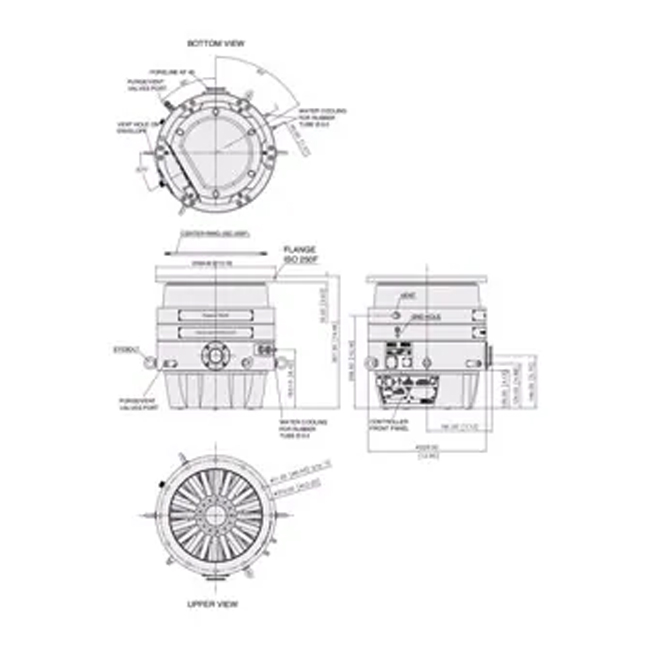

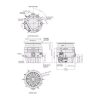

Turbo-V 3K-G

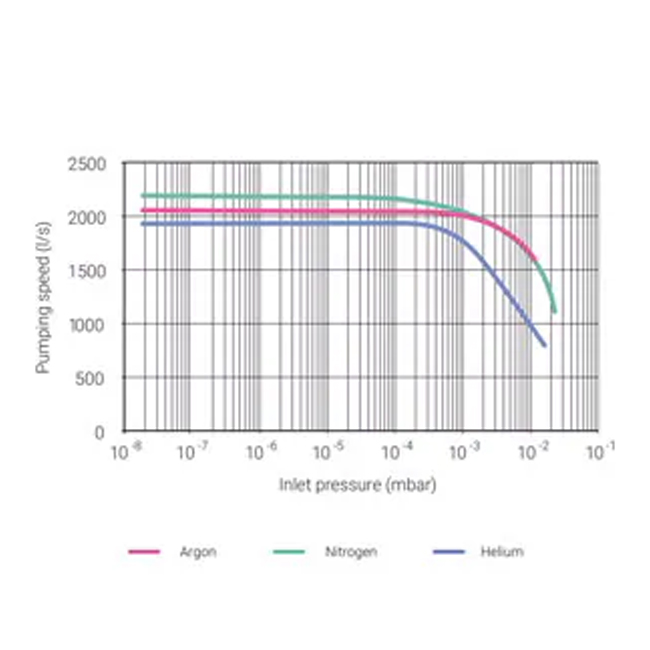

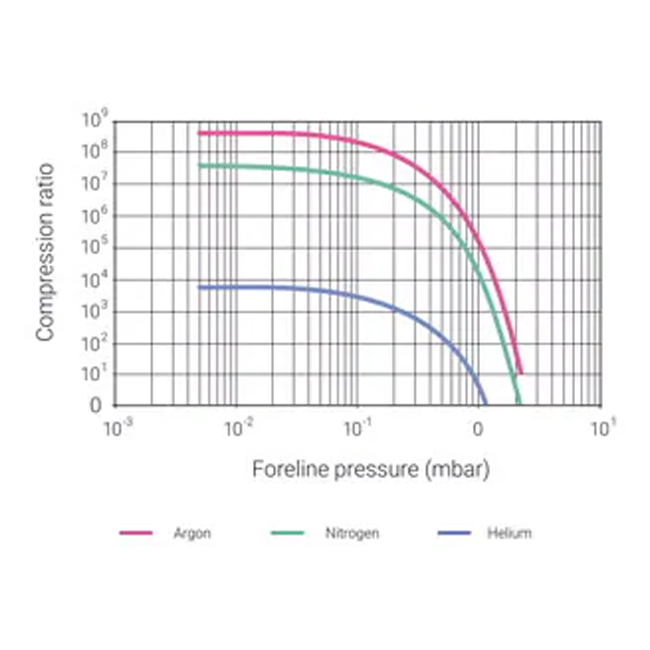

The Agilent high throughput turbomolecular pump, Turbo-V 3K-G, is a dedicated vacuum pumping system, designed specifically as a turbo pump for thin film deposition equipment. Its pumping stages, and the entire pump structure, are optimized to work with very high flows of Argon under high temperature load.

This robust turbo pump is suitable for harsh manufacturing environments because of its rugged design. Typical industrial vacuum coating applications include physical vapor deposition (PVD), solar and flat panel display manufacturing.

The pump’s robust design and its advanced integrated electronics make the Agilent Turbo-V 3K-G the optimum pumping solution for the vacuum coating industry.

Tiếng Việt

Tiếng Việt