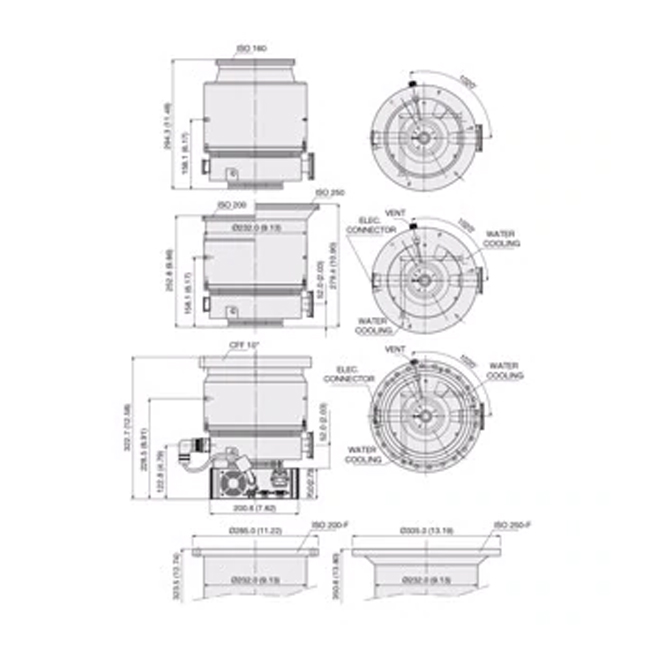

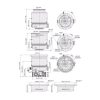

Turbo-V 1001 Navigator

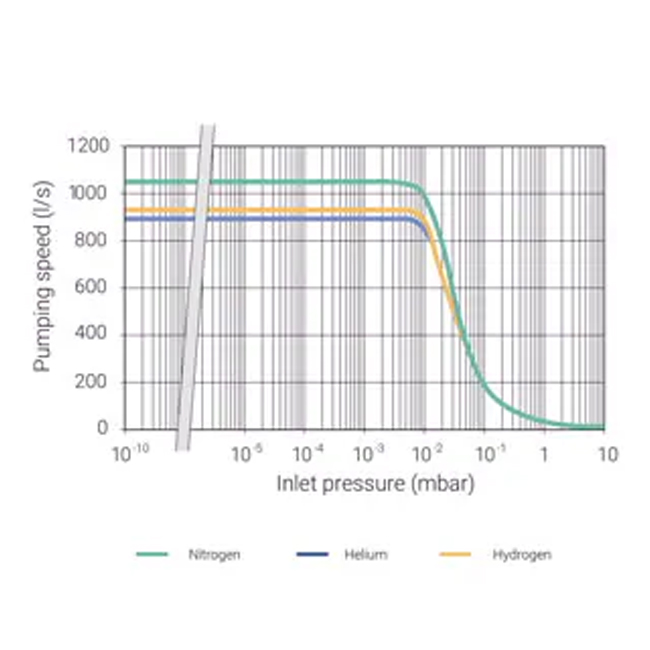

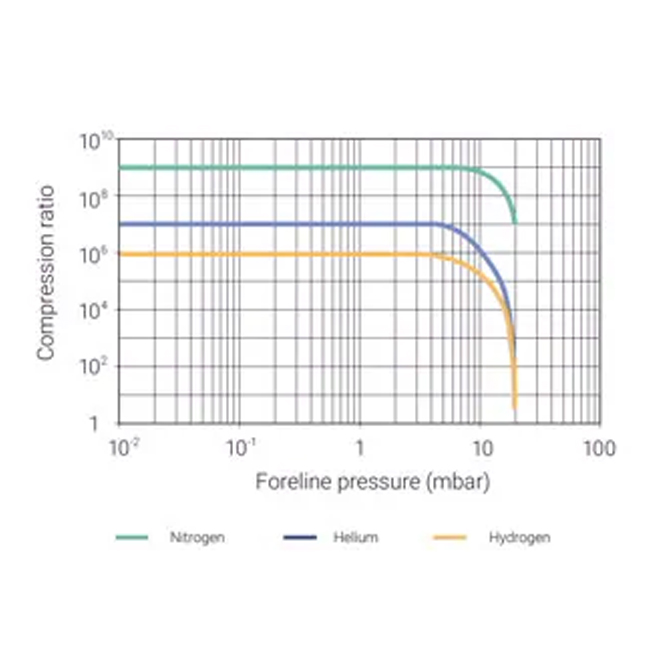

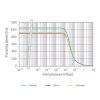

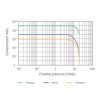

The Agilent 1000 L/s turbo pump provides high pumping speeds from 790-1,050 L/s (gas dependent), and includes the latest technology offerings in the Navigator line. The pump is optimized for high-compression ratio and consequent low base pressure, high-throughput and high foreline pressure. It is designed to be oil-free and contamination-free, and to have very high reliability with the ability to operate in any position without materials stress.

Applications for this turbo pump include high energy physics and research, nanotechnologies, mass spectrometry, industrial vacuum processing, semiconductors and electron microscopy.

Tiếng Việt

Tiếng Việt