TwisTorr 704 FS

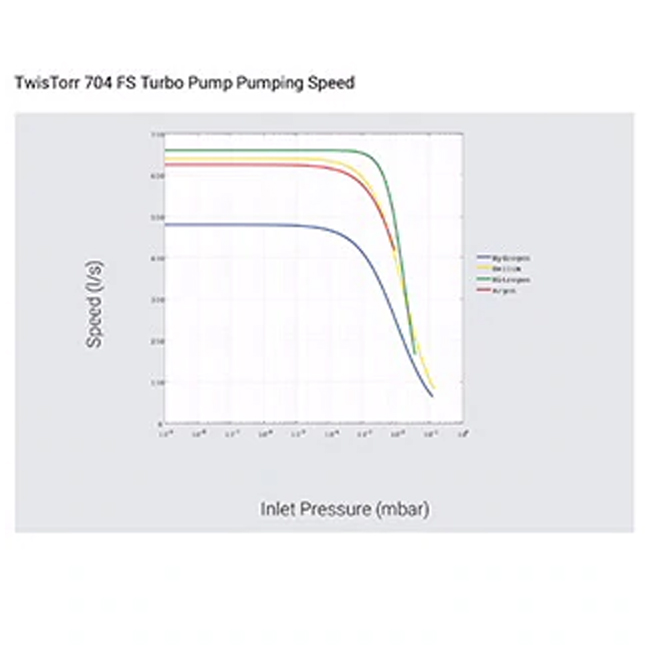

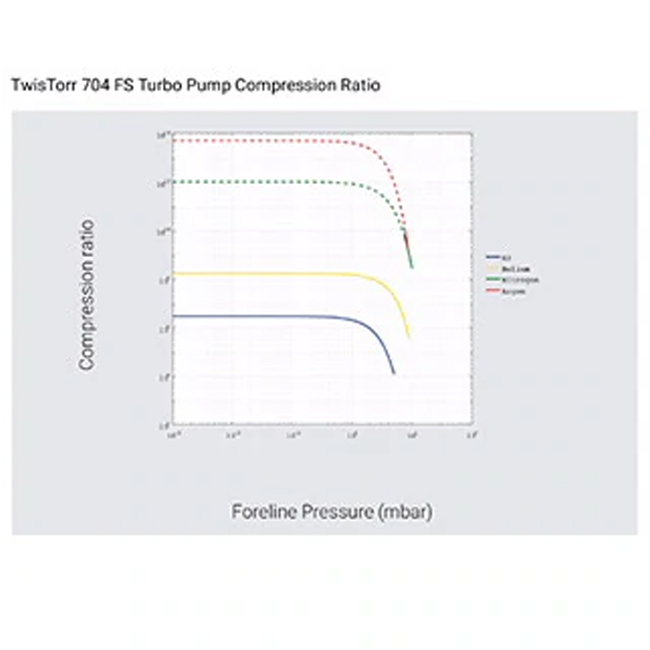

The Agilent 700 L/s turbo pump, TwisTorr 704 FS, combines TwisTorr drag stage technology and Agilent Floating Suspension (FS) to provide high performance, reliability and economy. This medium turbo pump delivers high vacuum performance thanks to the synergy between turbo technology and innovative TwisTorr drag stages. Floating Suspension assures low vibration and acoustical noise for compatibility with sensitive instrumentation and work environments.

This 700 L/s turbomolecular pump is perfectly suited for a wide range of applications, including research and development, UHV systems, nuclear research, ion implanters, surface analysis, electron microscopy, and cryogenics.

Tiếng Việt

Tiếng Việt